Purpose:

Ensures that drill pipes are fit for standard drilling operations under moderate conditions.

Scope Includes:

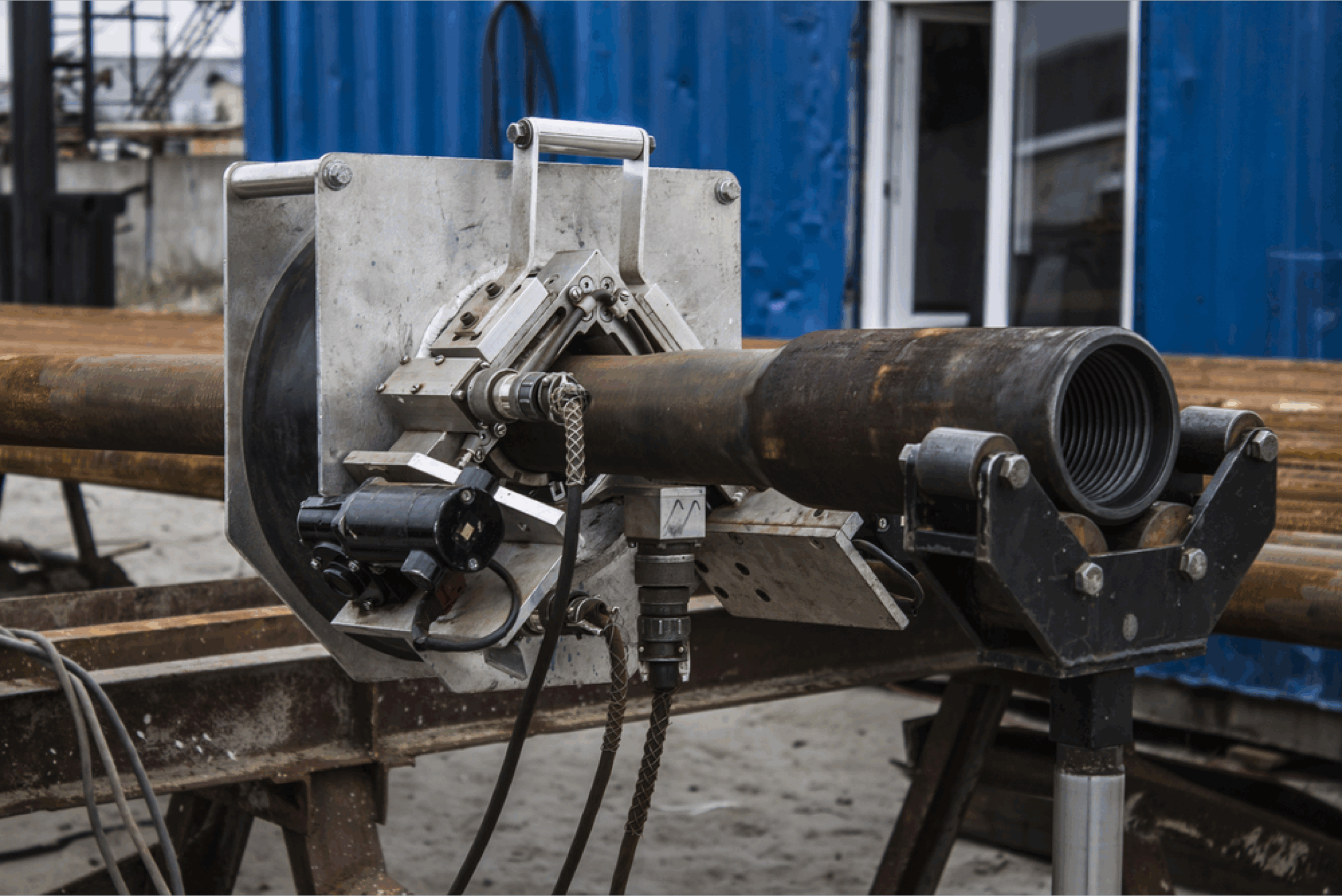

Full visual and dimensional inspection of pipe body and tool joints

Magnetic Particle Inspection (MPI) of critical areas

Thread gauging and inspection

Hardbanding condition assessment

Best For:

Routine maintenance cycles and pre-job verification for normal drilling environments.

Purpose:

Provides enhanced detection of subsurface flaws and fatigue to ensure reliability under demanding drilling conditions.

Scope Includes:

All Category 3 procedures

Ultrasonic Inspection (UT) for internal flaws and wall thinning

Detailed OD/ID measurement and ovality checks

Hardness testing and fatigue crack evaluation

Best For:

High-torque, high-pressure drilling environments or when extended drill string life is required.

Purpose:

Delivers the most comprehensive level of inspection, suitable for critical, high-stress, or offshore operations where equipment failure could have severe consequences.

Scope Includes:

All Category 3 & 4 procedures

Full-body ultrasonic testing and wall thickness mapping

Advanced thread profile analysis and recertification

Metallurgical evaluation of tool joints

NDT of weld areas and heat-affected zones

Best For:

Offshore drilling, deep wells, HPHT (High Pressure High Temperature) environments, and end-of-life drill pipe recertification.