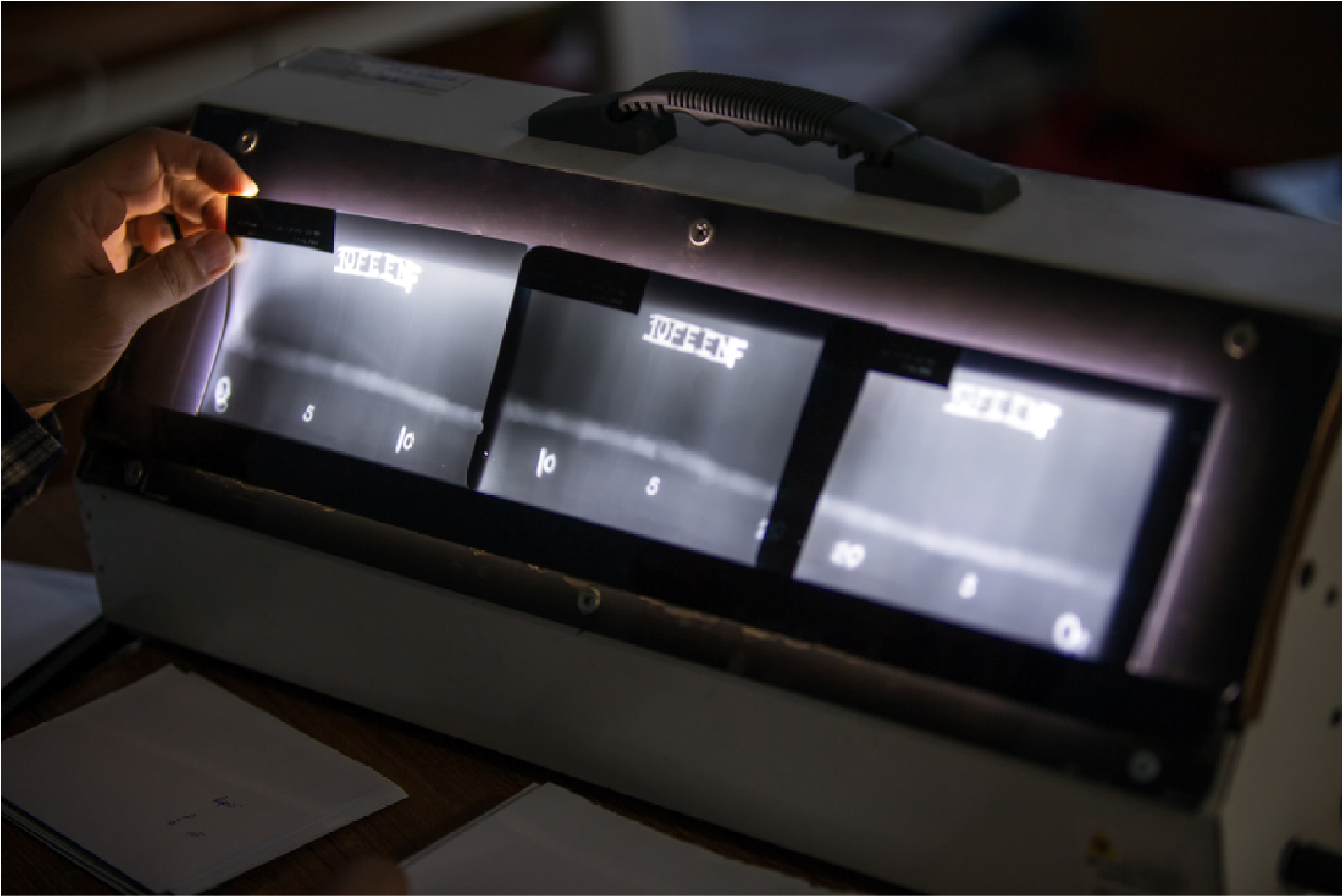

Radiographic testing is performed using Conventional Gamma Radiography with Iridium-192 isotopes, and wall thickness gamma radiography employs Cobalt-60 isotopes for heavy wall components. Conventional X-ray radiography is available upon request. For proximity radiography, the SCAR system is utilized. All radiography technicians are registered with ANEA (Associação de Energia Atómica Nacional) and operate equipment calibrated to meet required standards.

Ultrasonic testing is employed to detect flaws in castings, forgings, welds, and various components. Inspections may be conducted pre-service or during operation. Pressure piping surveys include boilers, tubes, and piping to evaluate remaining wall thickness, allowing for accurate determination of system and component integrity.

Magnetic particle Testing is a Non-Destructive Testing (NDT) method used to detect surface and near-surface discontinuities in ferromagnetic materials. It involves magnetizing the material and then applying fine ferromagnetic particles, which are attracted to any magnetic leakage fields caused by defects.

Dye Penetrant testing is performed using both color contrast and fluorescent methods. Various consumables are used including water washable, solvent removable, and post-emulsified products, ensuring reliable detection of surface-breaking defects.